CUSTOM?CUTS

Published 5:00 pm Wednesday, March 16, 2011

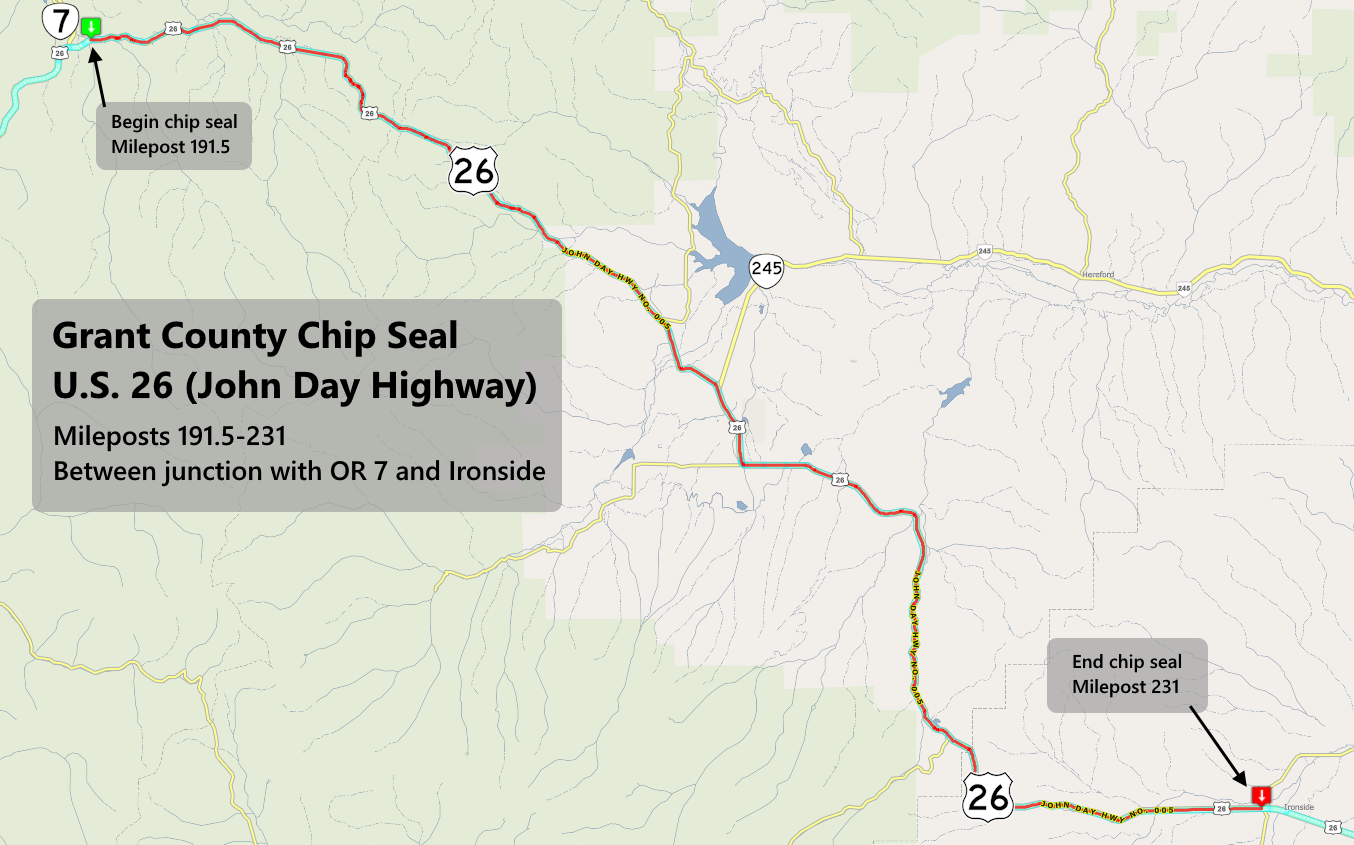

- An automated chopsaw cuts Pacific Albus logs to length on the Log Merchandiser Line before entering the Upper Columbia Mill in Boardman.

BOARDMAN The depressed market for wood products has the Upper Columbia Mill in turtle mode: head down, operating with a skeleton crew that produces less than capacity.

But with a sawmill set amid the 26,000-acre poplar farm near Boardman and a planer at the Port of Morrow, the mill is poised to take advantage of new markets, a recovering economy and the industrys trend toward lumber grown on private industrial land or in farm-like settings.

A collection of investors called GreenWood Tree Farm Fund owns the mill and the surrounding plantation. The mill exclusively uses timber grown onsite, where plots grow for 12 years.

To my knowledge, were the only mill captive to one specific location in the lower-48, said sawmill Manager Kerry Hart. Were a totally integrated operating site.

The advantages of such a system are many.

The average log haul distance from the plantation is about three miles, and the trucks need not conform to load-size rules that govern trucks on public roads. The mill never wants for a steady supply of lumber; once a plot is cut, workers replant it with the latest fast-growing hybrid. The mill could harvest 2,000 acres a year; currently it cuts between 1,000 and 1,500 acres.

The kiln and planer at the Port of Morrow are only 10 miles away, adjacent to the freeways, rail lines and barges that transport the boards elsewhere. The whole operation is efficient and uniquely suited to its spot near Boardman.

I think that in the future, this would be a niche-type model that will grow over time, Hart said.

Trademarked Pacific Albus, the poplars average 10 inches in diameter at harvest. At the mill, they pass through a series of scanners that allow a computer to find the optimal lengths and cuts considering each trees sinuosity and size.

You could stand around all day and try to figure how to do that for each log, Hart said. The computer does it in a nanosecond.

Logs are cut in 8, 10 or 12-foot lengths, sawed, edged and tossed onto a conveyer to be stacked for the kiln about 600 logs per hour at present, although the mill could handle more than 1,000. Human intervention in the process is minimal; workers are there mostly to monitor the process and untangle the odd boardjam.

The mill employs 60 people who earn around $17 per hour. Not only does the mill provide much-needed jobs, it has added substantially to Morrow Countys tax base. Port of Morrow General Manager Gary Neal estimated GTFFs capital investment at around $35 million.

Once the mill begins turning out the 80 to 100 million board feet it is capable of every year, the Upper Columbia Mill will be one of the largest hardwood sawmills in North America.

GTFF is always on the lookout for new markets for Pacific Albus, which is considered a soft hardwood. At present, the mill ships dried and sanded boards to secondary manufacturers who turn them into non-structural products such as moldings, ceiling grids, furniture and snowboards.

At least half of the mills boards end up in China, Vietnam and other foreign countries. The mill sells wood chips to pulp mills for use in paper products.

Self-contained operations such as the Upper Columbia Mill and the poplar farm may grow more common in the future, as harvests on public land diminish.

According to Paul Oester, an extension forester for Oregon State University in La Grande, lumber harvests from public lands are a fraction of what they were 10 or 15 years ago, for a variety of reasons. That has not been good news for mills surrounded by public lands, such as the Kinzua Heppner Mill, which closed in 1999.

Private industrial operations have picked up that slack. Theyve also paid for research into growing trees faster and healthier in a forest-type setting. Most private lumber enterprises still meet stringent environmental requirements. For example, they must protect streams and retain a certain number of snags broken trees to provide habitat for wildlife.

Because GTFF grows trees for only 12 years, its considered an agricultural operation, not a forest. As such, it conforms to a different set of rules, but it is still Forest Stewardship Council certified.

Most people now would like to know that their wood product is coming from a sustainable operation, Hart said. So this is our answer to the environmental community and ourselves.